Stain Gauge or Strain Gage?

- Weighing News

- Sep 9, 2024

- 3 min read

There is a debate on how “strain Gauge” should be spelled. Should it be “Strain Gauge or Strain Gage.” The purpose of this post is to provide a little bit of research history on the advent of the strain gauge or strain gage. Through some research, it seems the proper terminology and spelling should be strain gauge, and maybe there was some industry “marketing” influence on this topic.

The strain gauge or strain gage was independently invented by two people in 1938: Edward E. Simmons was a research assistant at the California Institute of Technology (Caltech). Arthur C. Ruge, a professor at the Massachusetts Institute of Technology (MIT)

Key Points about the Invention of the Strain Gauge or Strain Gage:

Simmons developed the concept in 1936-1938 while researching the stress-strain behavior of metals under shock loads at Caltech.

Ruge had his "eureka moment" on April 3, 1938, while trying to measure stress on water tank models for earthquake engineering research at MIT.

Both men independently came up with the idea of using thin metallic wires or foils bonded to a surface to measure strain.

Simmons and Ruge are credited as the inventors who shared the original patent.

The device was initially called the SR-4 strain gauge, with "SR" standing for "Simmons-Ruge" and "4" representing the four people involved (Simmons, Ruge, and their respective assistants).

While Simmons appears to have developed the concept slightly earlier, both men are recognized as co-inventors due to their independent and nearly simultaneous work. Their invention in 1938 marked the beginning of modern electrical resistance strain measurement technology.

Ruge and his colleague Alfred de Forest founded Ruge Consulting in 1939 to manufacture and commercialize the SR-4 strain gauge.

Ruge Consulting produced the first commercial shipment of strain gauges or strain gages—a 50,000-piece order—in 1941.

Then, around 1955, Baldwin-Lima-Hamilton bought Ruge Consulting and the rights to the SR-4 strain gauge or strain gage, renaming the company BLH Electronics Inc

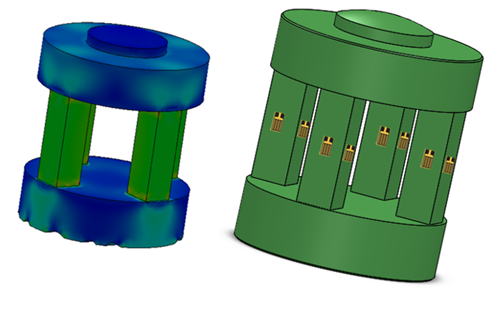

An example of strain gauges on a multi-column load cell.

Strain gauges (also spelled strain gages) are sensors used to measure strain or deformation in an object. Here are some critical points about strain gauges and their applications:

How the Strain Gauge or Strain Gage Works

Strain gauges consist of a thin metallic foil or wire attached to the surface of an object.

When the object deforms, the strain gauge deforms as well, changing its electrical resistance.

This change in resistance is proportional to the strain and can be measured using a Wheatstone bridge circuit.

Advantages of the Strain Gauge or Strain Gage

Accurate and reliable for measuring small strains

Versatile - can measure strains from micro to macro levels

Easy to install using adhesive bonding

Can be Cost-effective and durable

Applications of the Strain Gauge or Strain Gage

Strain gauges are used in many industries and applications, including:

Structural testing and stress analysis in aerospace, automotive, and civil engineering

Load cells and force sensors

Torque and power measurements on rotating equipment

Weighing systems in manufacturing and transportation

Medical devices like dialysis machines and syringe pumps

Monitoring bridges, buildings, dams, etc. for safety

Aerospace testing to verify CAD and FEA simulations

Types of Strain Gauge or Strain Gage

There are several types based on construction and mounting:

Foil strain gauges (most common)

Semiconductor strain gauges

Vibrating wire strain gauges

Bonded and unbonded gauges

And more

Considerations of the Strain Gage or Strain Gages

Proper installation and calibration are critical for accurate measurements

Environmental factors like temperature can affect readings

Multiple gauges are often used to measure strain in different directions

Strain Gauge or Strain Gage Conclusion

In summary, strain gauges are versatile sensors that enable precise strain and stress measurements across many engineering and industrial applications. Their ability to convert tiny deformations into measurable electrical signals makes them invaluable for structural analysis, product testing, and safety monitoring.

Article & Image Source : Click here

Comments