Load Cell Error Per Degrees of Rotation

- Weighing News

- Aug 2, 2021

- 2 min read

Most users of load cells understand that the load applied should be straight up – and down in almost all cases. But sometimes the application calls for a non – vertical load, or perhaps there’s something not quite right about the installation that makes the load angle suspect. In those situations, how does one answer the question, “How far off am I?”

The following example will focus on around, differential-bending load cell often referred to as a DB cell. However, all load cells are susceptible to error caused by loads that are out of alignment.

Let’s say for example that you have a DB cell with 10,000lbs capacity. It might look something like this, with an arrow sticker or engraving on the end where the load is applied. The other end is the ‘fixed’ or mount end, and the large-diameter section in the middle is the ‘can’ or cover.

Underneath the cover is where all of the load cell circuitry is hidden away and protected from the elements. Without going into a lot of detail about how it all works, it’s enough to say that the circuit is made of strain gauges and other resistors wired into a Wheatstone bridge .

The strain gauges are positioned exactly on the top and bottom of the cell – that’s how they are able to measure 100% of the load that is applied. If the bar were to be rotated away from the top-dead-center while the load stayed vertical, the strain gages would no longer be exactly on the top and bottom anymore. As a result, they would only be able to sense a smaller proportion of the total load.

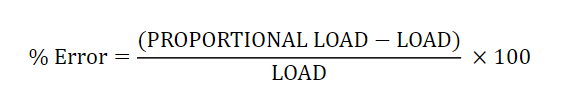

That proportion is calculated by using the formula:

To bring it all together, the error per degree of rotation for a 10,000lbs capacity load cell is summarized in a graph on the following page. Then, the next graphs show a generalized application of the percent error, including a close-up of the 0° to 30° degree range.

Comments